Outstanding VCSEL technology

The concept of VCSEL technology has been invented in the late 1970s by Prof. Kenichi Iga and has emerged from the research labs in the mid 1980s. Since then VCSEL became the the dominant laser source in short-reach fiber based datacom and optical sensing, with shipped quantities of billions of lasers built into various products of our every day's life.

Fundamental advantages of VCSELs:

- small active volume, thus low sub-mA threshold currents and operating currents in the low mA regime

- high modulation bandwidth in excess of of 20 GHz

- narrow optical spectra and small thermal wavelength shift

- control of modes and polarization, circular emission profile

- excellent reliability based on robust design by buried active medium and distributed mirrors (DBR)

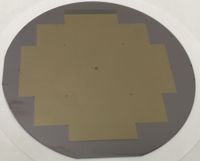

- on wafer testing capability

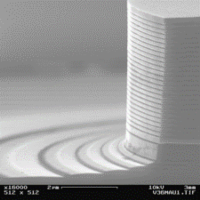

Major technological building blocks of VCSELs are the epitaxial stack of layers forming the vertical cavity and the active region and the current (and optical) confinement by selective oxidation of thin Al-rich layer(s).

VCSELs are superior light sources for many existing, emerging, and upcoming optical applications. In competition with light soures like edge-emitting lasers, fiber-lasers, gas lasers, LEDs, halogene lamps, and many others, it is important to understand and value the pros and cons of these different light sources in order to chose the most suitable solution for the task on hand.

VCSEL technology can be tailored to specific requirements and thus offers a huge benefit to a wide range of applications!

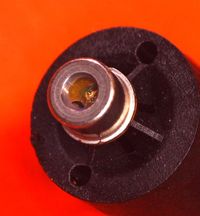

VCSELs can be packaged in a variety of TO packages, e.g., TO33, TO46, or TO39. Many different caps are available, including window caps with AR coated glas and tilt of the glas in order to avoid back reflections.

TO46 package with AR coated flat window TO39 package with TEC&Thermistor. AR coated tilted window

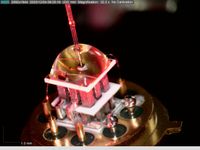

Single-mode fiber pigtail solution

is currently under development, where a single-mode VCSEL is butt-coupled to a single mode fiber including FC/APC or SMA fiber termination.

TO39 w/ TEC (left) VCSEL subassembly with single-mode optical fiber aligned and fixed to a single-mode VCSEL. A full pigtail (right) additionally comprises a strain relief and fiber termination (here FC/APC).

The coupling efficiency can be as high as 50% and due to index matching glue between VCSEL and fiber, as well as APC fiber termination, optical feedback is minimized.

Prototypes are available and we are looking forward to exploring the opportunities of single-mode VCSEL pigtails with you!